Standard Delivery

All structures are hand finished in our Bristol workshop and despatched with the following lead times.

-

Netting & Components - 3 to 5 working days

-

Cages - 10 to 14 working days

-

Polytunnels - 5 to 7 working days

-

Off the shelf products - 3 to 5 working days

Prices below are for mainland UK only.

Postcodes within Scottish Highlands, Industrial Scotland, Grampians and offshore UK locations will be calculated at checkout.

| Product type | UK mainland cost |

| Components & accessories up to 1m tube lengths | £4.95 |

| Netting | £12 |

| Small structures - Low fruit, veg, strawberry cages | £12 |

|

|

£15 |

| Construction Nets | £18 |

DELIVERY OUTSIDE THE UK

Knowle nets products can be delivered worldwide - if you are outside of the UK please contact our Customer Service team on +44 (0)1308 424342 for an international delivery quote.

For Construction Nets orders outside of UK Mainland, please get in touch with our Customer Service team for assistance.

TRACKING

Once you have placed an order on our website, you will receive an email confirmation and we will then e-mail you again when your order is sent, along with information on how to track your order with the courier and manage your delivery directly with them.

Please note, a signature will be required upon delivery unless we have authorisation from you that the goods can be left without signature in a secure location.

RETURN INFORMATION

If you are not satisfied with your purchase you can return the non bespoke item in perfect condition and in the original packaging within 21 days for a full replacement or a full refund. Return postage can only be refunded on non bespoke items in the case of damaged or faulty items or if the wrong items have been sent to you. Please email us at: info@knowlenets.co.uk or call us at: 01308 424342

Please note, bespoke / Made to Order Products include Fruit Cages and Cut to Size Netting. They are Non-Returnable Items and exempt from cancellation.

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.

Most of our netting is made from high density polyethylene monofilament which is black and contains ultra-violet stabilisation additives to a level of 2% which gives a protection of 400kLy. The intensity of UV radiation is measured in kLy (kilo-Langley), a unit of which represents how much UV radiation energy falls on a cm2 per year. In the UK this figure is about 70kLy compared to 220kLy in the Sahara.

Polyethylene has a temperature range from -100C to +115C. It is chemically inert and does not rot or absorb water. There are various methods used to manufacture nets. We stock three general types of nets, see below.

Knotted

This is the traditional way of making net. The process starts with making the twine. This can be a monofilament but is more usually a multifilament i.e. a number of strands are twisted together. The degree of twist and direction of twist are important factors. We use a Z twist (anticlockwise). The thickness of each filament is specified in Denier (as for tights). We use 600, 800 and 1000 denier filaments and the twines are either 2, 5, 6 or 15 ply.

The twine is wound on to 300 or 400 spools on the net making machine. The net is made by knotting the twine from adjacent spools one row at a time i.e. 300 or 400 knots per row. The knot we use is called a single English knot.

The net is complete when the spools run out or for longer nets new spools are added and the twine joined. As it comes off the machine the net has diamond shaped meshes. However this is generally not useful so the net has to be “squared”.

This involves joining one long edge of the net to the opposite long edge to make a cylinder. The twine and knot used are the same so this join is invisible. This can only be done by hand. The net is then cut diagonally in a spiral round the tube of net then when the net is laid out flat it can be pulled in to a square shape.

Woven Netting

This is a cheaper way of making a net because it is faster and requires no work by hand. The technical term for this type of net is Raschel which is a type of warp knitting in which parallel monofilaments are looped together in a zigzig pattern along the length of the net. Our Woven net is made from two strands of 500 denier filament looped together which is then interlooped at the mesh corners.

The net produced is a diamond mesh. It can not be “squared” so the net can stretch i.e. as opposite corners of the diamond are stretched widthways, the other corners will shrink lengthways. Windbreak is also a Raschel net but has the addition of crossways or weft strands. Our insect net is a standard weave with the weft monofilaments crossing the warp monofilaments at right angles.

Extruded Netting

This is a two stage process. The polymer is melted and forced through nozzles and cross strands then set at the joints as the material cools. The net is then reheated and stretched both length ways and widthways (Biorientation) to make a lighter weight net. This type of net is much more rigid than other types of net i.e. the meshes do not deform very easily.

Our standard off-the-shelf cages are available in 0.25m increments up to a maximum size of 9m x 9m.

Our customer services team is available to answer any questions if you require a cage for a larger garden or commercial application.

Trust Knowle Nets

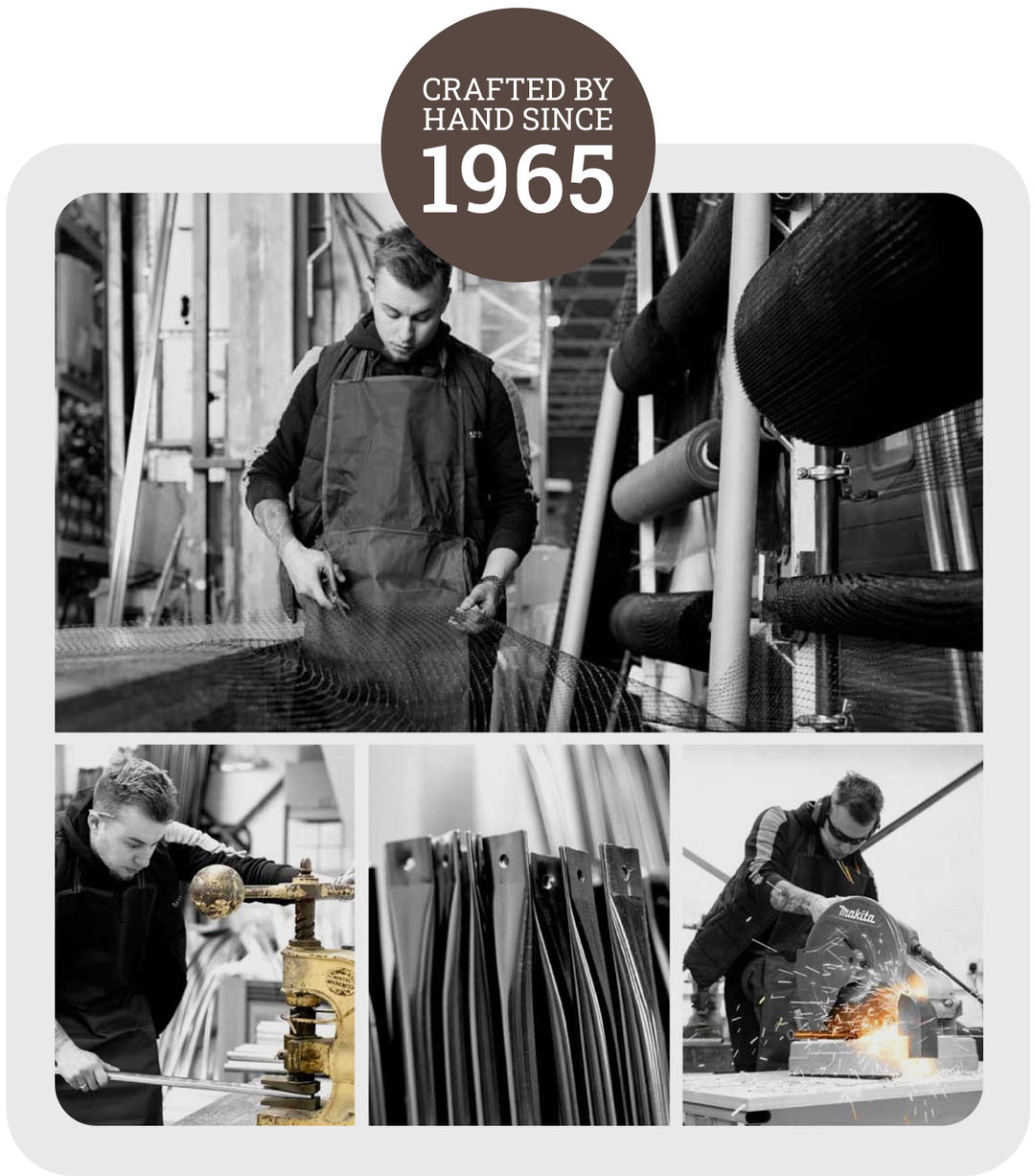

Our heritage can be traced back to 1965 at Knowle Farm Bridport, Dorset - the home of net making since the 9th century.

This tradition of hand finishing continues to this day in our exceptional modern Bristol workshops where all netting and tubes are cut by hand to fit your exact sizing. Each order is carefully packaged with clear instructions for easy installation.

Knowle Nets structures have unique tapered ends to the top tubes, allowing all poles to be joined directly. A much stronger structure built to withstand years of work and weather, backed by our 10 year structural guarantee.